For producing pressed Paneer, AGIPL offers a full range of industrial Paneer making equipment that can be used to make Paneer, ensuring maximum homogeneity in the products obtained and high performance in the production.

Our dairy equipment is making Paneer as per your requirement.

It is also extremely versatile and can always be adapted to respond to the demands of a changing market. In each project, the degree of automation is adapted to suit the technical and investment requirements.

Description

With our vast experience in this domain, we have enabled us to serve our clients with a broad array of Milk Coagulation Vat.

The offered vat is widely demanded by our clients for its precise design and low maintenance cost.

The offered vat is available in various sizes, as per the requirements of our esteemed clients.

High grade basic materials are utilized by our professionals, along with contemporary production equipment to design the entire range.

Mainly used in milk processing industries, client can avail this plant from us at market leading rates.

Description

With our vast experience in this domain, we have enabled us to serve our clients with a broad array of Milk Coagulation Vat.

The offered vat is widely demanded by our clients for its precise design and low maintenance cost.

The offered vat is available in various sizes, as per the requirements of our esteemed clients.

High grade basic materials are utilized by our professionals, along with contemporary production equipment to design the entire range.

Mainly used in milk processing industries, client can avail this plant from us at market leading rates.

Description

Do not let the whey filled with lactose, nutrients and other vital vitamins go to waste. With our whey collection trough, you can effectively collect all the whey during mould/Hoops filling and reuse it for manufacturing other products.

This is a manually operated trough that you can customise according to your requirements by simply reaching out to us.

Description

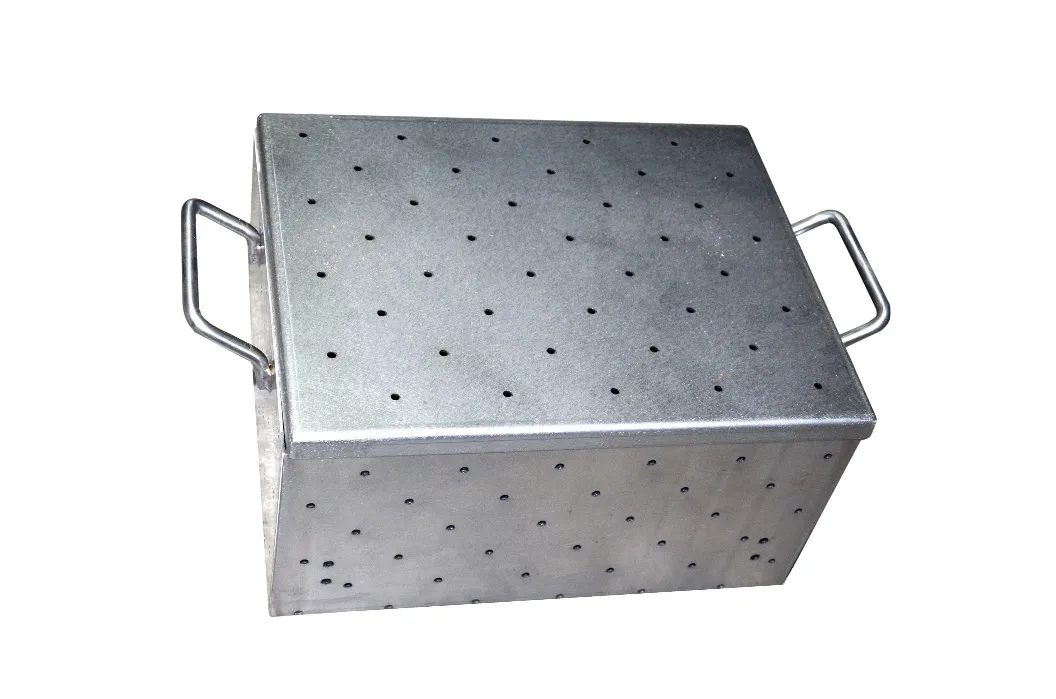

The quality of the mould greatly affects the final suppleness of the Paneer. With this in mind, our team has imported a micro-perforated mould that creates the most delicious and perfect blocks of Paneer. We use high-quality materials to maintain the health and hygiene of all the blocks made using the mould. Our micro-perforated mould has excellent durability and resistance to deformation.

You can readily prepare blocks that match your requirement. Plus, it also eliminates the waste created by moulds that are not representative of the final shape of the product. Our standard capacities include 9 kg, 10 kg, and 15 kg moulds. However, you can also get customized moulds that cater to your needs just by reaching out to us.

Description

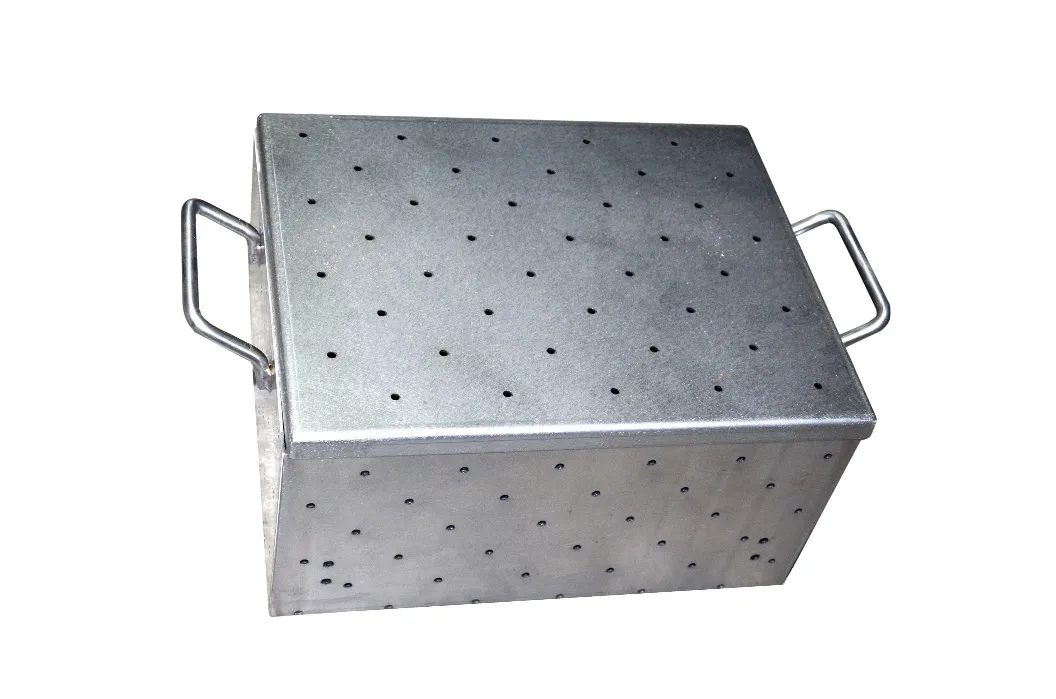

Increase the density and hence the quality of every paneer you make with our specially designed SS hoops. The stainless steel body helps prevent the chances of corrosion. Whereas, the natural ductility of the SS304 material lets you apply high pressures to arrive at the best paneer you have ever made. Plus, the easy to clean build, lets you keep your production’s hygiene levels at the finest.

The three-component design is simple, compact, and more importantly lightweight. You can customize it based on your requirements, just by letting us know. Our standard capacities include 9 kg, 10 kg, 12 kg, and 15 kg. The perfect size to satiate all your demands.

Description

Paneer press is used to remove moisture from the product with pneumatic pressing process.

Description

Apply the right pressure on the hoops to get the right structure on your end product. With our pneumatic paneer press machine, you get immense control over the pressure applied over the hoops. This lets you produce different paneer products using the same press machine.

The size and station of this press machine depend on your requirements. We also amend the design according to the capacity you need. So, you wouldn’t have to compromise on anything when it comes to choosing us.

Description

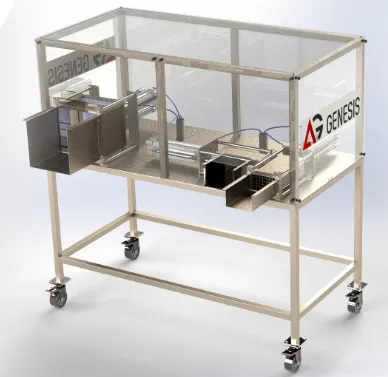

Prevent manual errors in applying the right pressure on the hoops using the fully automatic PLC based paneer press machine. It uses cyclic pressure with regulation & control on time to eliminate whey from the mould through micro perforation as per the process requirement and gives you bouncy and juicy paneer.

The micro-perforated mould size for this fully automatic paneer press machine is 300 X 300 X 100 mm. You can just reach out to us to customise the capacity easily.

Description

Quicken the process of removing the lids of micro-perforated moulds without incurring any damage to the paneer blocks. Our specially designed two to five-station model lets you remove lids continuously without any breaks for a long time. Thus, doubling up your productivity effortlessly.

This is a semi-automatic machine that reduces labour requirements and efforts. You can remove lids from micro-perforated moulds of sizes 300 X 300 mm. Plus, you can open 300 moulds/hr on average, leading to better productivity.

Description

Perfectly cooling down the paneer block makes it more fluffy and thus more sellable. Paneer Dipping vat is used for the Cooling of Paneer Block (Temp. 72 to 80℃) filled with Chilled water of 3 to 4℃. Timing period for the Cooling is 2 Hours. Paneer dipping vat significantly retains the original softness of the block. Moreover, our design is hygienic & allows for the flexibility in continues paneer making process.

Our standard capacities are 1 KL, 1.5 KL, 2 KL, 3 KL with pneumatic lifting arrangement with safety standards. Much faster & hygienic than conventional cooling methods.

Description

Perfectly cooling down the paneer block makes it more fluffy and thus more sellable. Paneer Dipping vat is used for the Cooling of Paneer Block (Temp. 72 to 80 Deg. C) filled with Chilled water of 3 to 4 Deg. C. Timing period for the Cooling is 2 Hours. Paneer dipping vat significantly retains the original softness of the block. Moreover, our design is hygienic & allows for the flexibility in continues paneer making process.

Our standard capacities are 1 KL, 1.5 KL, 2 KL, 3 KL with pneumatic lifting arrangement with safety standards. Much faster & hygienic than conventional cooling methods.

Description

The vats are filled with chilled soft water and continuously circulating through the cooling PHE for the maintenance of required temperature within the vats automatically.

The Paneer block from the hoops are then be de-hooped and put in the Paneer block cooling vat.

The blocks are cooled to less than 15°C in the vat.

After each day operation the soft water is drained out and fresh soft water is filled.

After completion of cooling of Paneer blocks, the blocks are removed/taken out manually from the cooling vat and manually taken to a packing area.

Description

The vats are filled with chilled soft water and continuously circulating through the cooling PHE for the maintenance of required temperature within the vats automatically.

The Paneer block from the hoops are then be de-hooped and put in the Paneer block cooling vat.

The blocks are cooled to less than 15°C in the vat.

After each day operation the soft water is drained out and fresh soft water is filled.

After completion of cooling of Paneer blocks, the blocks are removed/taken out manually from the cooling vat and manually taken to a packing area.

Description

Perfectly cooling down the paneer block makes it more fluffy and thus more sellable. Paneer Dipping vat is used for the heating of Paneer Block filled with hot water. Timing period for the heating is 10 to 15 min. Paneer dipping vat significantly retains the original softness of the block. Moreover, our design is hygienic & allows for the flexibility in continues paneer making process.

Our standard capacities are 1 KL, 1.5 KL, 2 KL, 3 KL with pneumatic lifting arrangement with safety standards. Much faster & hygienic than conventional cooling methods.

Description

Manually cutting paneer blocks lead to improper shapes and more importantly result in waste of precious protein. Hence, we have come up with an efficient design that slices and dices the paneer blocks as per your requirements using a pneumatic cylinder.

You can cut paneer blocks of size 100g, 200g, 500g, and 1 kg. The capacity of the machine ranges from 400 to 500kg/hr. Letting you produce more units within a small time frame.

Description

Manually cutting paneer blocks lead to improper shapes and more importantly result in waste of precious protein. Hence, we have come up with an efficient design that slices and dices the paneer blocks as per your requirements using a pneumatic cylinder.

You can cut paneer blocks of size 100g, 200g, 500g, and 1 kg. The capacity of the machine ranges from 400 to 500kg/hr. Letting you produce more units within a small time frame.

Description

Have more control over making cuts on your paneer blocks. This pneumatic cylinder and blade assembly help you achieve higher productivity rates through power cuts and slices. Through the HMI screen, you can effortlessly specify the size and the machine will make precise cuts accordingly of any output require weight.

This PLC-based paneer cutting machine enables you to program the specifications prior to operation. You can cut and slice paneer blocks of 100g, 200g, 500g and 1 kg. The capacity of our well-designed machine ranges from 200 to 600 kg/hr as per the output sizes.

Description

Do not waste your paneer blocks just because they are out of shape. With our paneer crushing machines, you can rework the paneer block. This is an initiative to reduce waste in the food industry. Moreover, reworked paneer blocks have the same texture, quality and taste as those freshly prepared.

This semi-automatic machine is a boon to everyone dealing with losses due to improper processing. This mechanism crushes the paneer efficiently without affecting their capability to bond again. With this by your side, you can crush up to 200 kg of paneer per hour without much labour effort.

Description

Mould washer is design for washing Micro Perforated Mould are using in dairy industry.

Remove production gaps by continuously washing the moulds at high speeds. Our continues mould washer make it easy to remove any curd particles left over from the previous production cycle. Thus, ensuring sanitary production of high-quality paneer at all times.The washing process includes 3 stations for efficient washing.

We can easily customize the capacity of the continues mould washer as per your plant production requirement.

Description

You can now move your finished paneer blocks with ease across the facility using a dedicated paneer trolley. The parts are easy to remove. Thus, facilitating sanitation and disinfection after every use. We offer you the flexibility of choosing the size you need, and we will readily customize the units accordingly.